Two days ago, I received the old milk analyzer LM2 (right picture) sent back by the customer. The equipment as a whole seems to be intact as before. The display panel and keys are not damaged, and the operation can be used normally after the machine is turned on.

Our engineer received this old milk analyzer and repeatedly lamented that this equipment has some history, and its appearance is still intact. I don't know whether it is the user's care for use or the equipment's durability (probably both).

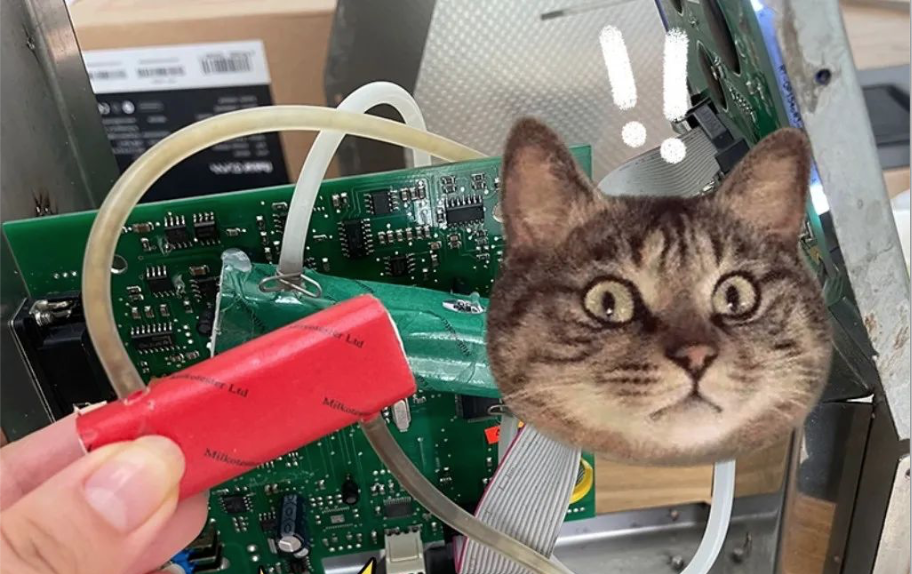

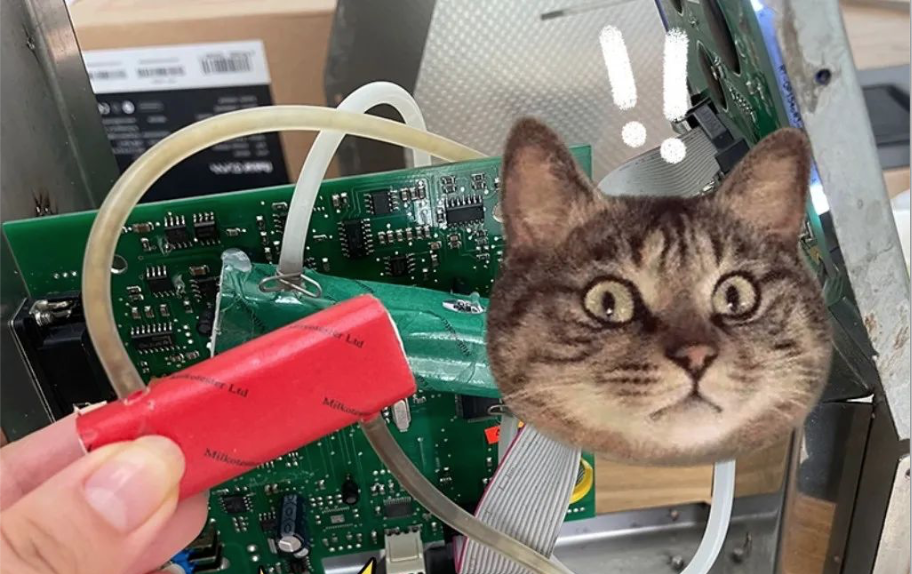

In order to answer the customer's question, the engineer took apart the equipment, and was surprised to find that the inlet and outlet had become moldy and black, and gave off a bad smell!

No wonder the customer feedback that the measured milk data is not accurate. The milk analyzer has not been properly cleaned for a long time, leading to mildew in the tube and sensor, resulting in data errors. In this way, the composition of fresh milk cannot be correctly detected, which will cause certain impacts on dairy farming and milk collection process.

So our engineers immediately replaced the sensor and the suction and discharge pipe and cleaned the milk analyzer (you can see the cleaning and maintenance process in the video below).

The cleaning process of milk analyzer is not troublesome. After each use of the equipment, use a small measuring cup to take about 10ml clean water, and clean the alkaline reagent every day, and clean the acidic reagent every week (choose the quick cleaning mode on the milk analyzer).

Commonly used milk analyzer reagents are liquid and powder (as shown below, red is acidic reagent and green is alkaline reagent)

Cleaning method:

1. Pre-rinse with enough water to remove milk residue

2. Circulate 1% (10g/) cleaning solution for 10-20 minutes at a temperature above 40℃

Rinse thoroughly with running water.

Reagent ingredients:

> acid:

PH value: surfactant PH value (1%) slightly 1.6

Ingredients: sulfamic acid, phosphate, sulfate, surfactant, defoaming agent

> alkaline:

PH value: surfactant PH value (1%) is slightly 11.5

Ingredients: carbonate, phosphate, silicate, surface active agent, defoaming agent, disinfectant

! Special note: Keep container sealed away from moisture.

Material compatibility: stainless steel is not affected by solution; Aluminum is slightly corroded.

Liquid powder is suitable for all types of milk and inspectors can follow their instructions for acid and alkali washing. It is very effective in removing milk stones and hard water deposits, thus improving the hygiene of all milk picking equipment.