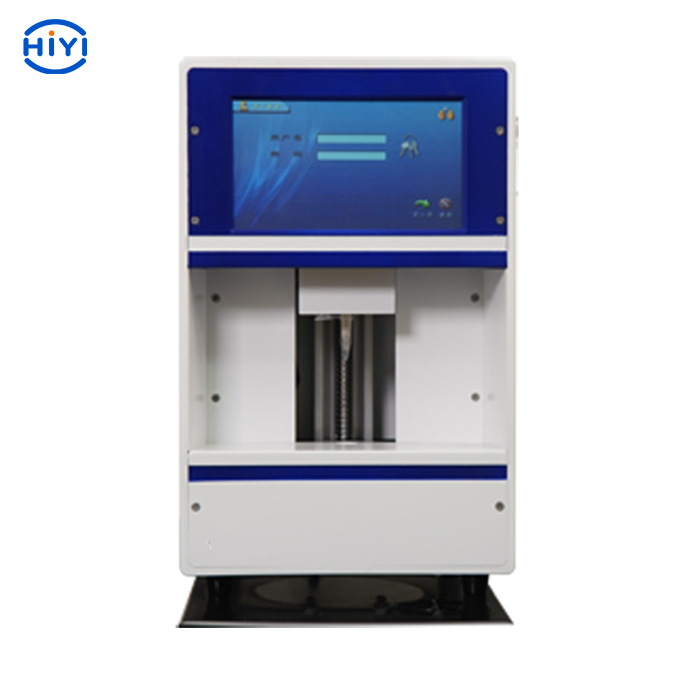

Laboratory Class 100 purification glove box

The fan draws in the air from the FFU item (closed loop) and sends the clean air back to the box after being filtered by primary and high efficiency filters.

Excellent uniform gas distribution performance

Automatic air speed adjustment

Filtration efficiency 99.999%

The cleanliness of the gas in the box reaches the national standard of 100 grade.

| Types | Box specifications (L*W*H)mm | Transition Module Specifications (mm) |

| Single station (single side) | 1220*750*900 |

| Large cabinФ360*600 |

| small cabinФ150*300 |

| Three gloves (one side) | 1500*750*900 |

| Large cabinФ360*600 |

| small cabinФ150*300 |

| Duplex (single sided) | 1800*750*900 | 2440*750*900 | Large cabinФ360*600 |

| small cabinФ150*300 |

| Duplex (opposite) | 1220*1000*900 |

| Large cabinФ360*600 |

| small cabinФ150*300 |

| Three stations (opposite) | 1500*1000*900 |

| Large cabinФ360*600 |

| small cabinФ150*300 |

| Four stations (opposite) | 1800*1000*900 | 2440*1000*900 | Large cabinФ360*600 |

| small cabinФ150*300 |

| Glove box with modular design can be freely combined; can be non-standard customization. |