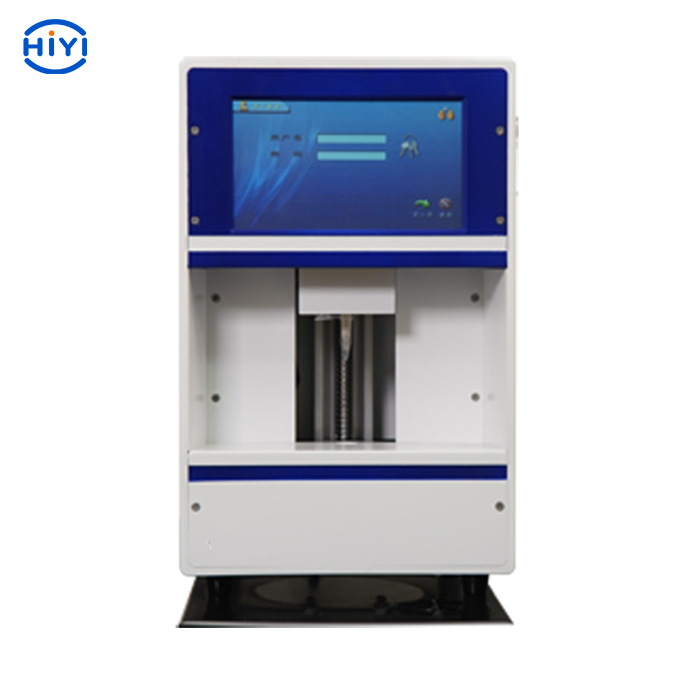

ZLJ-B330 Bench-Top Airborne Particle Counter

Overview:

ZLJ-B Series incorporate our Extreme Life Laser Diode Technology sensor to produce the industry’s long life-time laser diode.

The ZLJ-B330 is the industry’s 28.3 LPM 0.3 micron portable designed for continuous use.

ZLJ-B Series are adopted the industry’s UI (User Interface) to configure andoperate the instrument. The intuitive ICON-driven screens and menus are easy to learn and use, and support multiple languages.

They can store up to 5,000 records of particle count data from up to 8 particle channels and the configurable recipe database can store up to 50 recipes for sampling and reports. All data can be quickly and reliably transferred to a computer.

Data transfer to a USB Flash Drive can be accomplished by using the software.

Flexible communication with these instruments is made possible by the integrated Ethernet, RS-485, USB and WIFI.

ZLJ-B Series are designed, manufactured and calibrated to ISO14644 to ensure particle counting accuracy.

Feature:

0.3µm to 10.0µm sensitivity

Big Flow Rate:28.3L/min; 50L/min; 100L/min

Simultaneous Display of up to 8 Particle Sizes

Secure Data Transfer via USB Flash Drive

Extreme Life Laser Diode Technology

Thermal Printer

Stainless Steel Construction

Multiple Communication Interfaces - USB, RS-485, Ethernet and USB Flash Drive

9.1-inch Color TFT Touch Screen Display

2000-record Data Storage Memory

User-Definable Printouts

Report Wizard for Cleanroom Pass/Fail Reports: FS-209E, ISO-14644-1

Multiple-language Support: English, Chinese, or others.Support language customization

Application:

Particle Counters are feature-rich instruments that are ideal for spot-checking inside of your critical environments or Indoor Air Quality applications. With its compact size and weight along with its sleek handle, you can utilize this unit with ease.

These units provide immediate results that allow you to proactively monitor your environment.

It's widely used in Automotive Manufacturing; Coating Processes; Paint Booth; Aerospace Flight and Space; Hardware Manufacturing; Flat Panel Display Manufacturing; Medical Device Manufacturing Electronic Industry (semiconductor factory, precision machinery production and processing, etc);Food Hygiene Industry (dairy products, plastic meat food, seasoning food, agricultural products, etc); Filter Manufacturers, inspection filter quality and efficiency, etc; and other areas of precision processing, precision testing required Clean Room (area), and other testing needs.

Technology:

| Size Range | 0.3 - 10.0 µm |

| Channel Sizes | 8-Channel: 0.3, 0.5, 0.7, 1.0, 2.0, 3.0, 5.0, 10.0 µm |

| Concentration Limits | 35,000 particles/L |

| Light Source | Laser diode (30,000 hours mean time between failure) |

| Calibration Count Modes | Meets ISO14644 calibration ,GMP-2010 |

| Date Storage | 2000 samples |

| Communication Modes | WIFI, RS-485,Ethernet, USB,Software |

| Environmental Sensors(Optional) | Temperature, Relative Humidity, Air Velocity, Differential Pressure,Battery or others |

| Reports | Pass/fail report wizard for ISO-14644 and FS-209E report formats |

| Alarms | Integrated alarm buzzer. Alarms on counts, low battery (optional) |