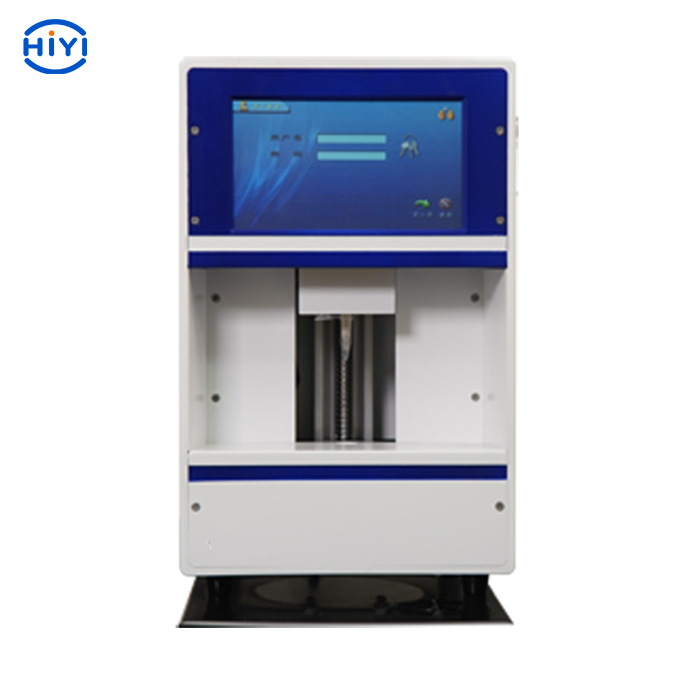

Automatic Culture Medium Preparation And Dispensing System

Product Description:

The fully automatic media preparation and dispensing system consists of a fully automatic media preparation instrument and an automatic flat dish dispenser.

1. Fully automatic media preparation instrument:

Brief description:

Minimises the space available for storage of finished petri dishes, eliminates the need to manage the storage of culture blood and ensures high quality media homogeneity. The ability to sterilise media quickly and gently and to precisely monitor and control parameters such as time, temperature and pressure during the sterilisation process ensures that all sterilised products are of the same high quality, and its intuitive graphical interface and programmable functions make it easy for everyone to operate the instrument.

Features:

Operating modes: with a choice of 2 main operating modes (standard mode and chocolate agar mode) and 2 additional modes (water bath mode and sterilisation mode) with your own parameters.

Medium sterilisation: guarantees fast and gentle preparation of standard and highly sensitive media.

Highly safe operation: before sterilisation begins, a programme automatically checks the gas tightness of the entire system.

Fast heating: efficient heating elements ensure rapid warming of the medium

Reliable sterilisation: Equipped with a powerful magnetic stirrer with adjustable stirring speed and direction, ensuring that media of different viscosities can be stirred evenly.

Rapid cooling: the rapid cooling system uses a highly efficient plate heat exchanger.

Aseptic media dispensing: a large auxiliary spout allows easy and safe addition of various additives such as antibiotics, blood, growth factors, etc.

Sterilisation data logging: Provides the tools needed for data logging, including sterilisation parameters, working status, etc., and supports long term data storage.

Cleaning and maintenance: Built-in cleaning programme for automatic sterilisation of the chamber, tubes and valves.

2. Automatic flat dish dispensers:

Brief description:

The Automatic Flatware Dispenser is a compact and highly automated flat blood dispenser that requires only a small amount of laboratory benchtop space and operates with its own explanatory instructions, just as all functions can be easily controlled via a graphical user interface. Once the flat blood dispensing process has been initiated, the complete system works steadily without operator intervention. The filling area of the dispenser is equipped with an external sterilisation light to ensure a clean filling area, and the configuration of 25 culture blood holders per compartment allows the complete dispensing system to be placed on an ultra-clean bench for the dispensing of culture media, ensuring that all operations are aseptic.

Features:

The reliable automated flat dish dispenser guarantees reliable, independent operation, with the flat blood being mechanically conducted through the system and monitored by a set of sensors throughout the dispensing process.

The automatic flat dish dispenser is perfectly matched to the fully automatic media preparation instrument, allowing you to dispense 1-45 litres of sterile media in a single operation for small to medium-sized laboratories or production.

| Capacity | 12L, Chamber 18L |

| Chamber size | Diameter 300mmx640mm. |

| Drum size | Diameter 260mmx600mm. |

| Sterilisation measurements | 70 - 130 °C, design temperature: 140 °C |

| Dispense temperature | 25 - 80 °C |

| Water bath temperature | 30 - 80 °C |

| Temperature accuracy | 0.1°C |

| Humidity excursion | 0.5°C |

| Time setting accuracy | 1 min. |

| Maximum working pressure | 2.5 bar. |

| Design pressure | 4bar. |

| Chamber sterilisation water | Deionised pure water. Automatic water inlet (pressure not less than 1 bar), high and low water level alarm |

| Cooling water connection | 2 points inner wire diameter 12 pta amine head. |

| Circulating water | Pressure not less than 1 bar white water. |

| Drain connection | 2-part inner wire diameter 12 pta. |

| Sterilising steel | 1.4301 / 1.4305 |

| Dispense port | Two, suitable for various dispensing requirements, one of which can also be used for aseptic dosing of materials. |

| Dispense hose | Inner diameter 6 mm, thickness 2 mm. |

| Material addition port | Straight and light 32 mm. |

| Stirring | Powerful magnetic stirring, high speed 240 rpm, low speed 120 rpm, infinitely variable. |

| Water cooling system | Water-cooled system with complementary pressure to maintain the pressure in the chamber during rapid humidification. |

| Safety measures | Unique lid inertia design, dual control of temperature and pressure, temperature above 80°C, pressure above 50 mbar, external lid cannot be opened, automatic locking, temperature above 50°C, pressure above 50 mbar, upper lid cannot be opened, automatic locking to ensure that the lid will not be opened accidentally during operation; over-temperature protection 130°C, temperature exceeds the set temperature 2.5°C white action warning, over-temperature white action power failure; safety valve open Pressure 1.7 bar, built-in safety valve does not accidentally injure the operator. |

| Media probe | The culture media preparation chamber is equipped with a flexible PT-100 temperature probe, which can be placed anywhere in the chamber. |

| Heating power | 3.6kW |

| Electrogen requirements | 2 2 0 - 2 4 0V, 50/50Hz, 20A |

| Dimensions | Length 555mm; width 700mm; height 980mm |

| Net weight | 85kg |