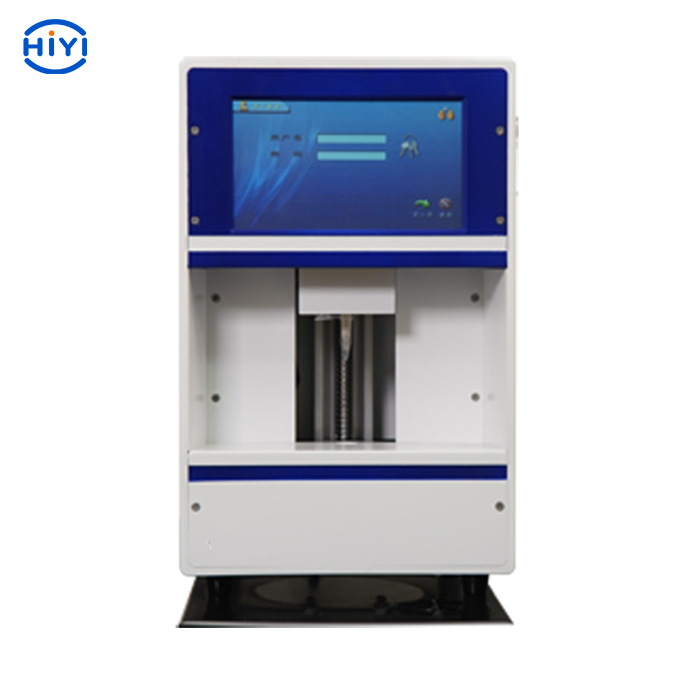

Explosion-proof Rotary Evaporator

R-2020Ex

Features:

High borosilicate 3.3 glass has good physical and chemical properties.

Main and auxiliary condensers, high efficiency triple-circulating condensing tube has bigger condensing area.

High borosilicate glass three-way flask, prevent flushing and bumping, ensure safe operation.

Patented technology of double sealing of Teflon (PTFE) and FV rubber ensures negative pressure level.

Auto switch valve makes continuous collecting possible without affecting vacuum degree and without stopping distillation.

The motor, heater, electric control box and liquid level switch are all explosion proof type, explosion�proof grade: ExdⅡBT4, all explosion-proof parts have certificates from manufacturer.

Motorized stainless steel water bath, has liquid level protection and anti-dry burning functions.

Quick-release valve for easy installation and removal of glass components.

PTFE discharge valve is corrosion resistant and contamination free.

Lockable casters, easy to move and lock.

LCD control panel

Model | R-2020Ex |

| Temperature range | RT+5~95C |

| Temperature and rotation speed | LCD display |

| Heating power | 4000W |

| Overall power | 4500W |

| Vacuum Leakage | ≤2kPa/h |

| Rotary motor power | 370W |

| Speed-regulation | Frequency control |

| Rotation speed | 20~130rpm |

| Condenser type | Vertical, main + auxiliary condensers high efficient triple-coil condenser |

| Condensing area | Main condenser: 0.948 m Auxiliary condenser: 0.358 m |

| Rotary flask | 20L, flange opening Φ125mm |

| Receiving flask | 10L |

| Water bath | One-mold piece, SUS304 ,Φ450mm×260mm |

| Water bath temperature stability | ±1.5 C |

| Lifting method | Motorized lift |

| Lifting distance | 0~160mm |

| Vacuum sealing (Patent technology) | PTFE + PTFE-Viton rubber |

| Discharge valve (valve plug) | PTFE |

Evaporating speed | Water | About 5.0 L/h |

| Ethanol | About 14.3L/h |

| Protection functions | Over-current, ground-fault, over-temperature, run-dry protection |

| Communication protocol | RS485 interface Standard MODBUS RTU communication protocol |

| Ex-grade of electric control box | ExdⅡBT4 |

| Protection grade of electric control | IP65 |

| Ambient temperature | 5~35C |

| Relative humidity | ≤ 70% |

| Movement | Lockable casters |

| Power supply | 3~,380V ,50Hz 1~220V/60Hz |

| Dimensions | 1210W×740D×2040H mm |