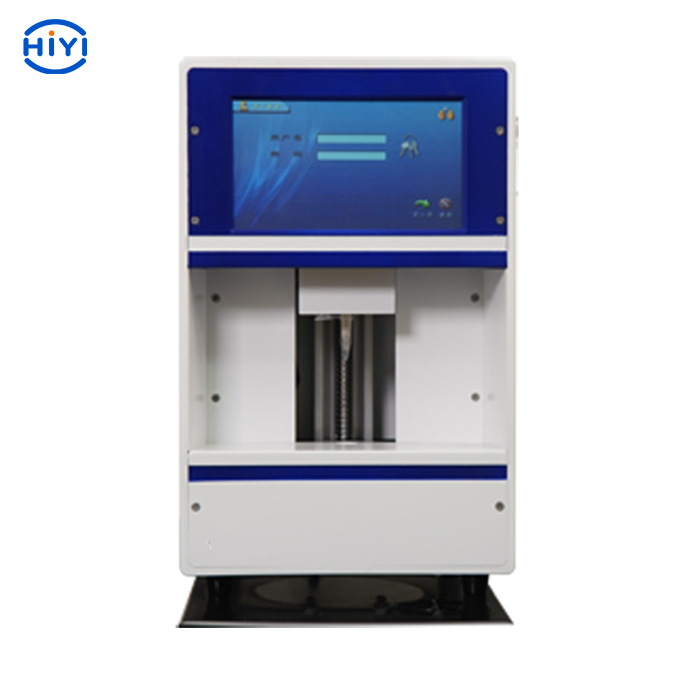

SP Genevac HT Series 3i Vacuum Evaporator

Intuitive touchscreen controls simplify your workflow, and with minimal maintenance requirements - and almost no user intervention required during a run - the HT Series 3i is the most innovative range of SP Genevac evaporators to date.

With built-in Dri-Pure®, anti-bumping technology, a high-performance vacuum pump, and touchscreen technology, never has your evaporation process been so effortless.

Features:

Intuitive touchscreen controls; 'Press & Go' feature with simplified manual and automatic programming means easy set-up and run

Save valuable fume hood space; integrated condenser means a smaller overall system footprint

Front opening door allows for easy and error-free access

Options for hydrochloric acid (HCl) resistance, Inert Gas Purge (IGP), and EXALT™ controlled crystallization

A wide range of sample holders for tubes, vials, flasks up to 500 mL, and bespoke FastStack™ holders for microtiter plates.

Minimized environmental impact thanks to a high-performance dry vacuum pump, and F-Gas compliant -75°C auto-defrost and draining condenser with R449A and R170 low Global Warming Potential (GWP) refrigerants.

Pre-programmed methods for ease of use, with user editable parameters enabling users to fine tune your methods for optimal performance

Application:

Parallel Chemistry

Post Purification Sample Handling

Controlled Crystallization

Environmental Analysis

Metabolism & Toxicology Studies

Natural Products Research Including Flavors & Fragrances

Oligo Synthesis

Compound Handling

| Maximum speed | 1415 rpm |

| Maximum G-force | 500g |

| Drive system | Direct drive |

| Motor drive | Multi speed inverter drive |

| Vacuum system |

| Pressure display | 0-1200mbar |

| Pressure control | Automatic 1mbar to atmosphere |

| System ultimate vacuum | 0.4 mbar |

| Bumping / foaming protection | Dri-Pure® |

| Temperature and control |

| Control range | Ambient +10°C to 60°C |

| Control accuracy | ±1°C (at 三 50ºC) |

| Temperature sensing | Thermocouple |

| Display range | 0°C to 60°C |

| End of method | Time or automatic |

| Process visualization | Graphical display |

| Condenser Data |

| Condenser temperature | Minimum -75°C |

| Refrigerant gas – stage 1 | R449A; GWP 1397 |

| Refrigerant charge – stage 1 | 0.320 kg |

| Refrigerant gas – stage 2 | R170; GWP 6 |

| Refrigerant charge – stage 2 | 0.041 kg |

| CO2 equivalent (CO2e) | 0.5 tonnes |

| Solvent compatibility |

| Boiling point range | 40°C to 200°C at atmospheric pressure |

| HCl | Resistant option required |

| Diethyl ether, Pentane | Requires Inert Gas Purge option |

| Dimensions |

| Width x Depth x Height | 660 x 710 x 840 mm |

| Weight (approximate) | 194 kg (varies with build options) |

| Services |

| Supplied with single power cable and plug | IEC 60309 / Nema L6-30P |

| Requires 32A power supply | 230V 50Hz / 220V 60Hz / 208V 60Hz |

| USB A | For data upload and download |

| Safety |

| Compliancy with BS EN 61010-1:2010 and | is CE marked |