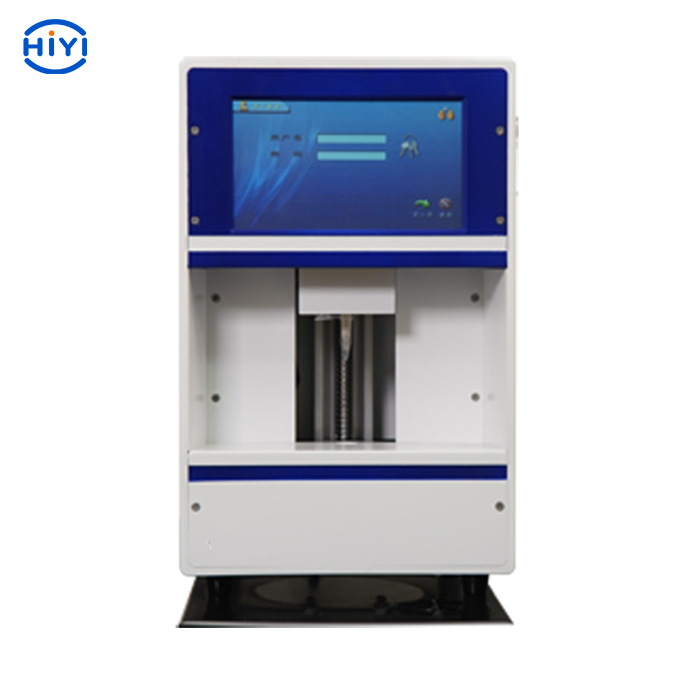

LUMiSizer All-in-One Dispersion Analyser

Because of an enhanced optical system, the LUMiSizer lets you analyse particle and droplet velocity distributions for creaming and sedimentation phenomena without the need of any material data and performs particle sizing (ISO 133182)

Run 12 samples at a time under a wide range of viscosities, temperatures, and real-world concentrations, The lUMiSizeris the only instrument in the world that allows you to obtain particle velocity distributions without having to know any material constants.

Features:

• Universal high-end analyser for science, R & D and QA/QC

• Direct, fast and objective characterization of any demixing phenomena

• Information within minutes and hours instead of months and years

• Reliable stability information up to 5000 times faster than by other methods

• Particle size information without material properties

• Particle susceptibility through superposition with magnetic fields

• For concentrated or diluted suspensions and emulsions

• For a large sample viscosity range

• Minimal sample volume required

• Various accessories and customizing options to fit your application

• Easy operation, comprehensive database solution

Application:

Characterization of very slow separation processes (months till years), very stable, very high viscous dispersions with very high concentrations and very small particles and droplets.

Determination of separation stability, velocity and particle size distribution or consolidation in one measuring step.

Particle characterization, particle size distribution, particle-particle interactions, hydrodynamic density and magnetic susceptibility.

Measurement of carbon black, ink, food, fine chemicals, abrasives, polymers, color pastes, sludges, slurries, cosmetics, pharmaceutical dispersions, biocells, carbon nanotubes and much more materials.

Tasks requiring high sample throughput.

Determination of particle size distribution according to ISO 13318-2.